Thrown Gold

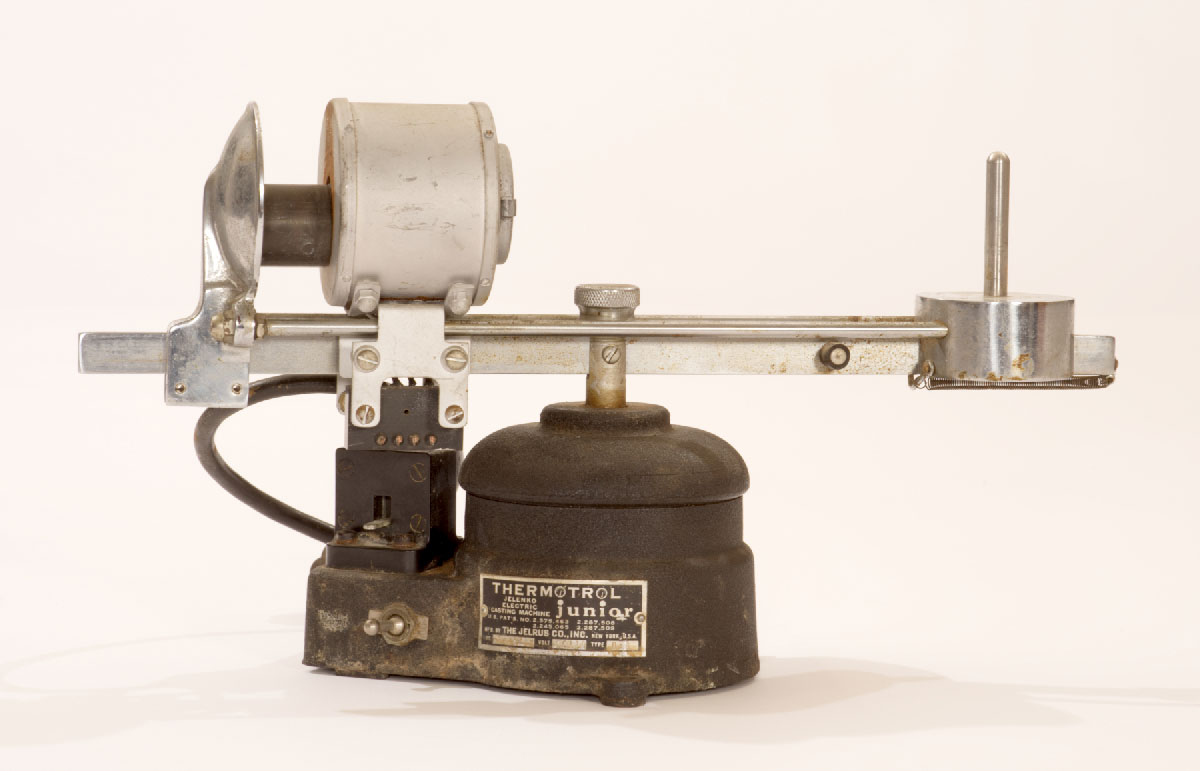

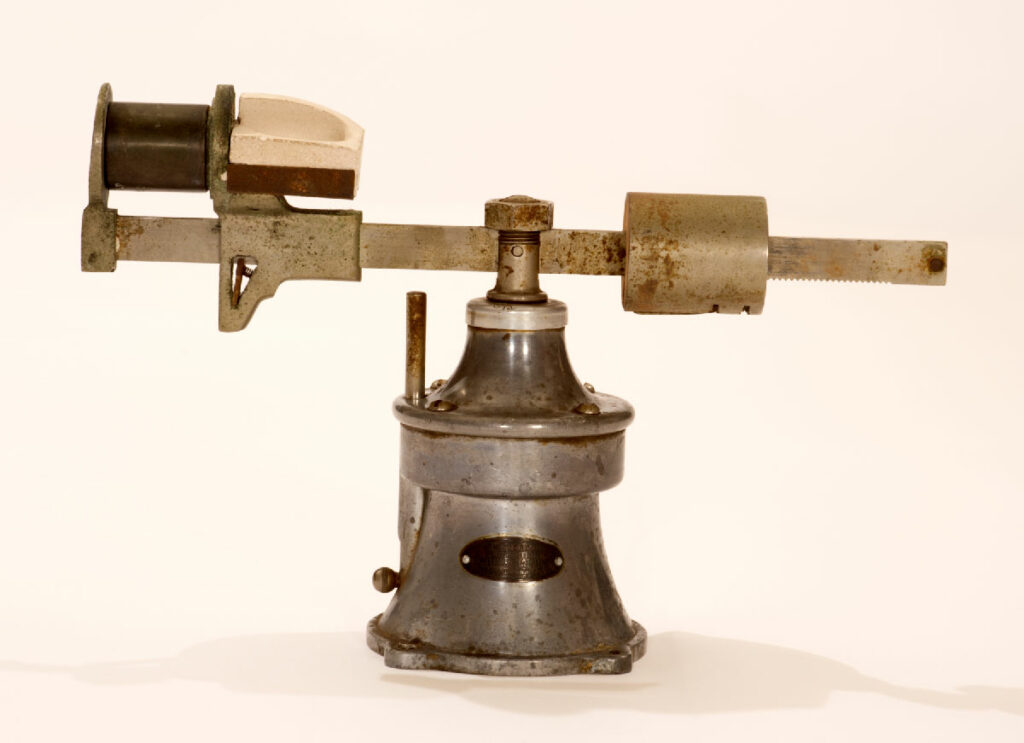

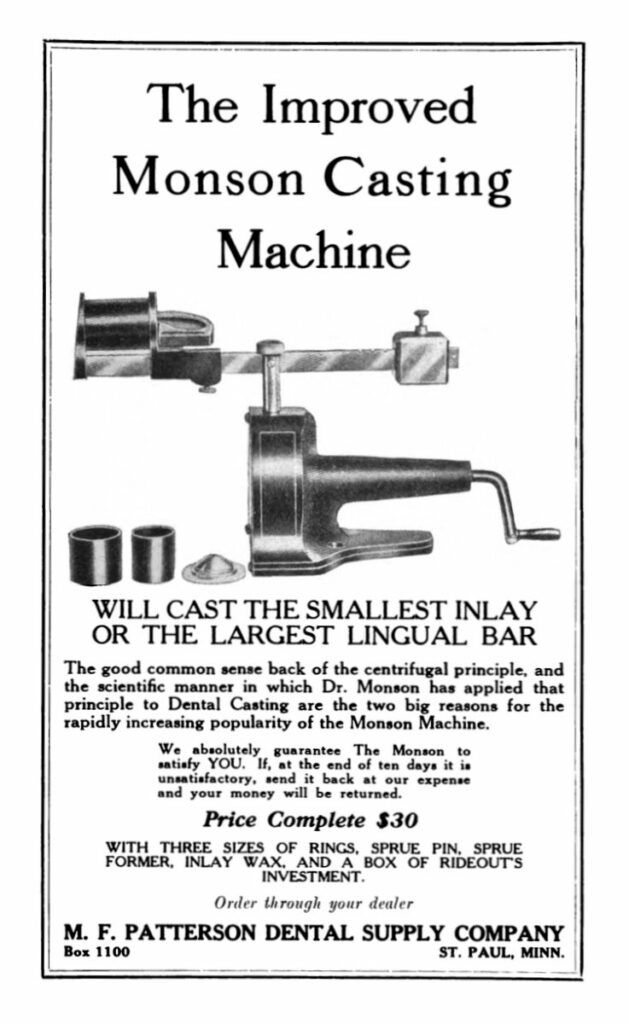

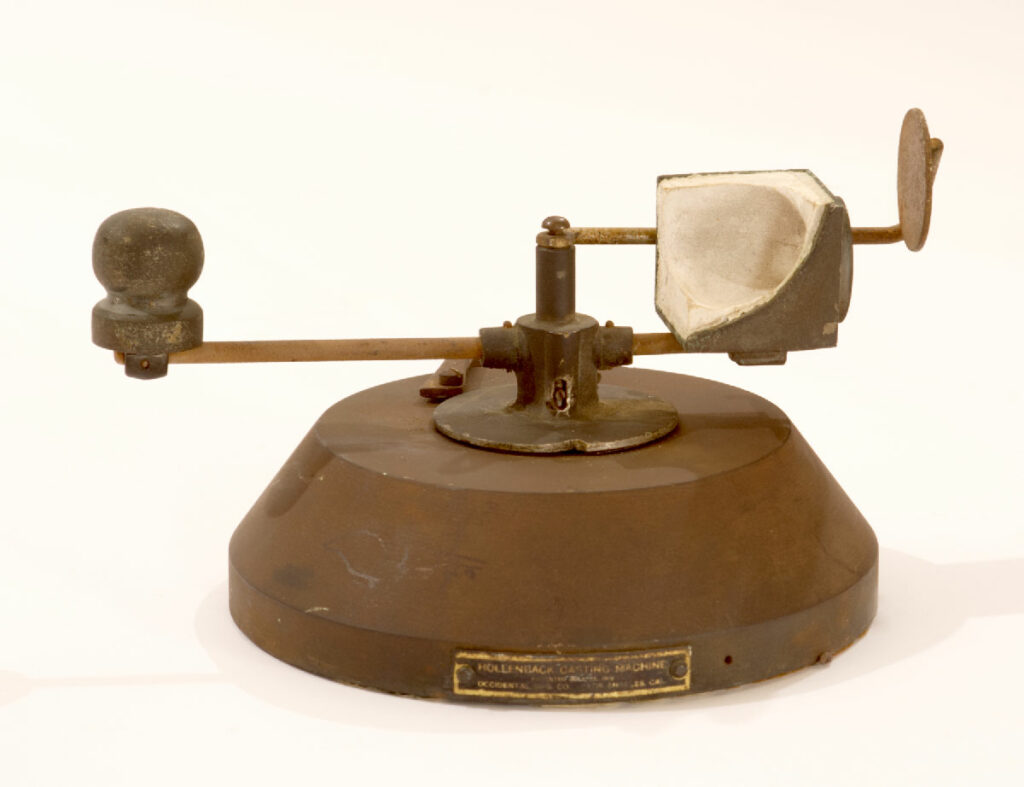

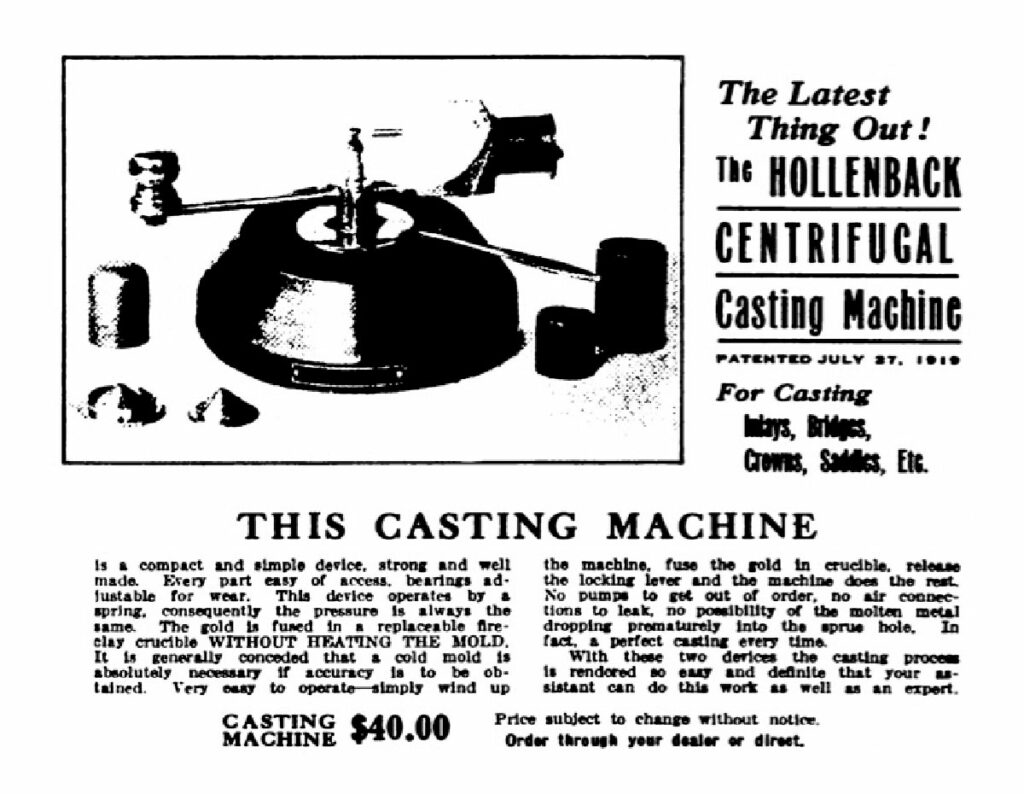

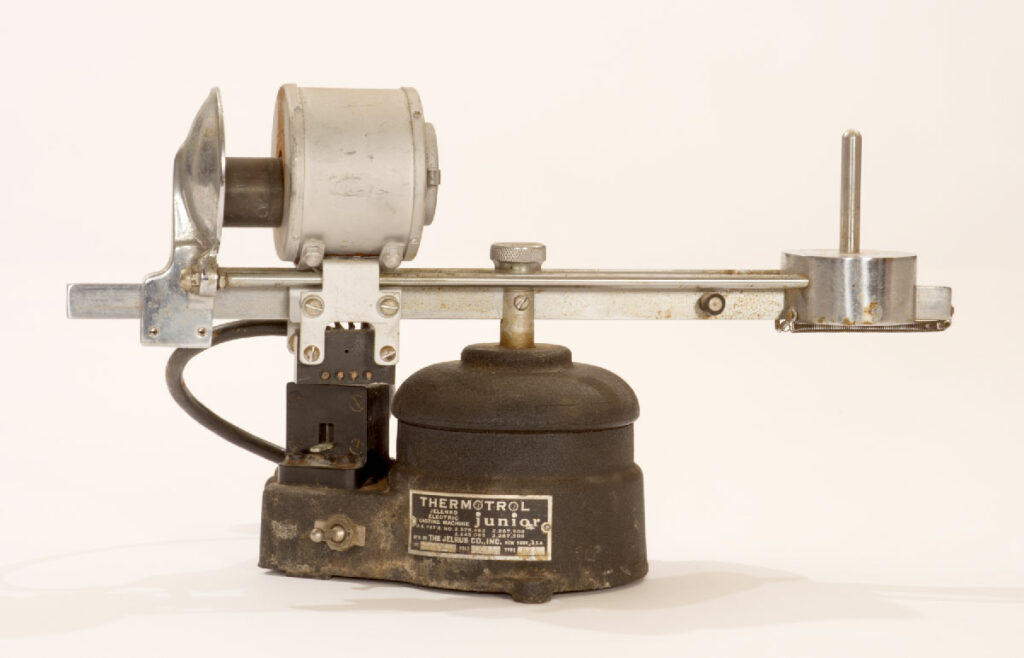

As mentioned earlier in this exhibit, the lost-wax casting technique proceeded by first investing (in a hard plaster “jacket”) a wax pattern inside a metal casting ring, then heating the ring in an oven to burn-out the wax, thereby creating a mold for casting inlays or crowns. The next steps required removing the hot casting ring from the oven, placing it onto the casting machine arm opposite a crucible, and filling the crucible with molten gold. Centrifugal force, caused by energetically spinning the casting machine arm, threw the molten gold into the open end of the casting ring. With successful casting, the molten gold completely filled the invested mold, making an exact replica cast of the inlay or crown pattern.

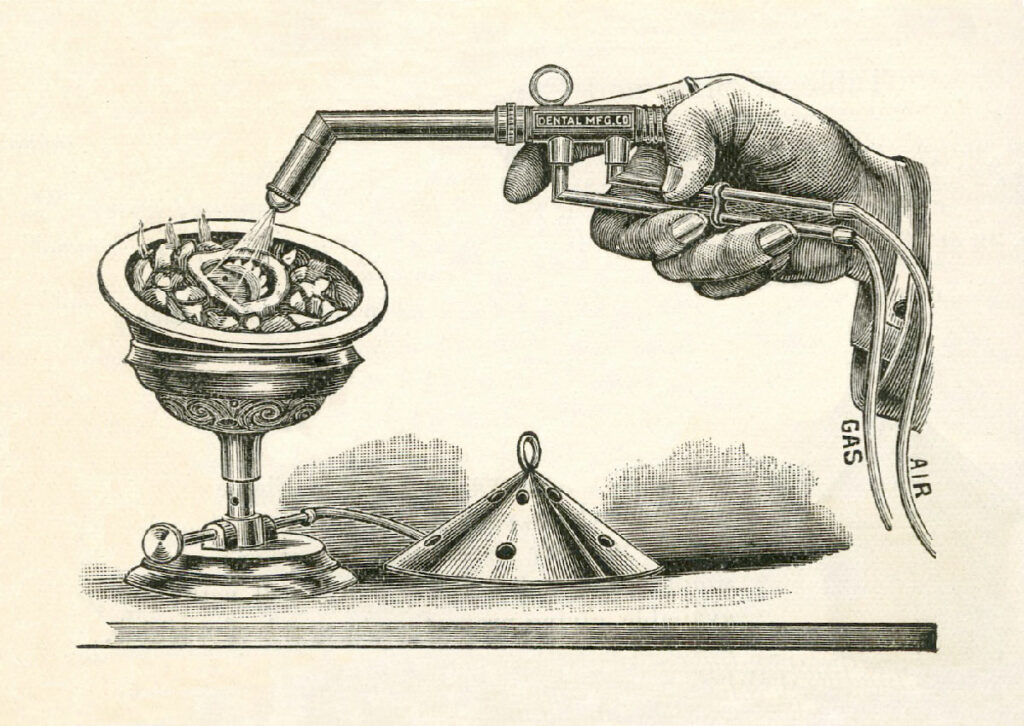

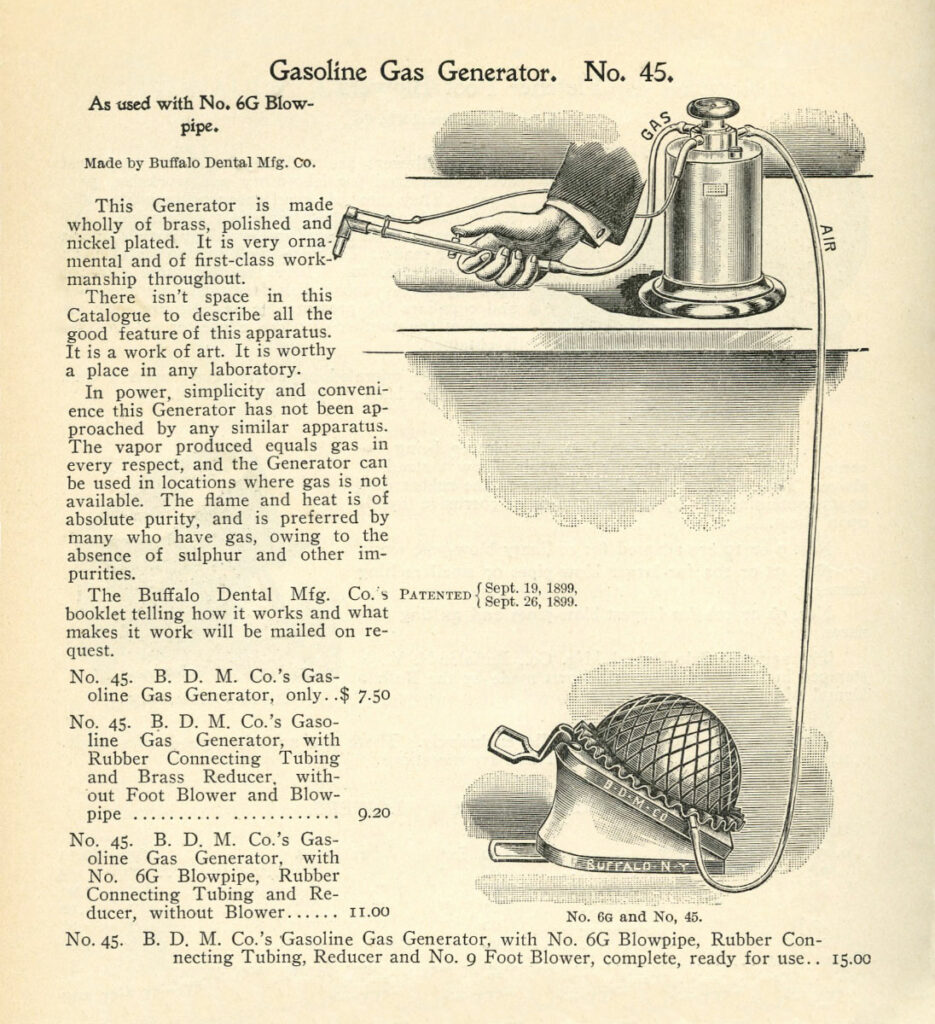

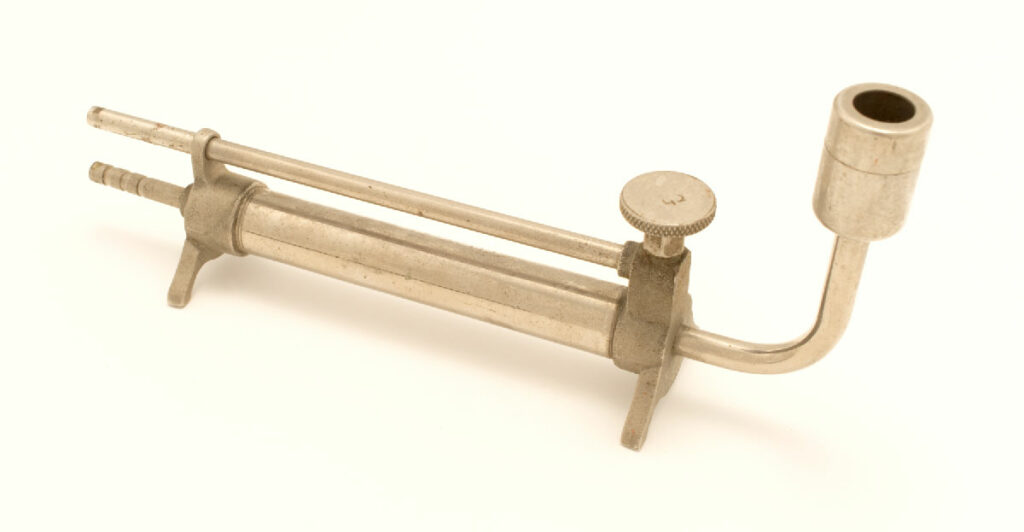

The blowpipe, aka blowtorch, was used to produce the high temperatures needed to thoroughly melt casting gold. The typical blowpipe had two gas fittings to carry flammable gas and air. A valve controlled the mix of gas and air transmitted. Increasing the air level increased the temperature. Those blowpipes with narrow tips produced a finer flame for precise soldering. Wider tips were used for melting larger pieces of gold.

Timing was a critical factor in the casting process. When melting the gold, the dentist looked for a “jiggly, marble-shape” to the molten gold, described as “the tiger’s eye.” At that point, the gold was ready to be thrown (E. Giachetti, personal communication, April 27, 2022). Simultaneously, the investment ring had to be taken hot from the oven and quickly placed opposite the crucible. Otherwise, the contrast in temperature between the ring and the thrown molten gold would result in a poor casting.

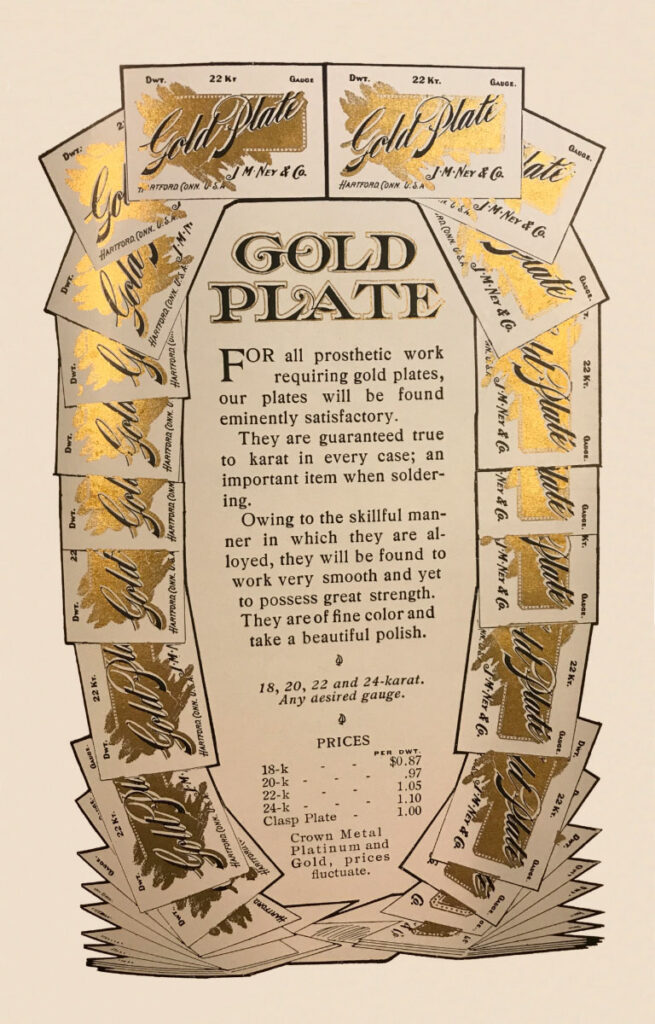

Shown here are several heating devices, and related materials, used by dentists operating casting machines, including gold plate, a ladle, blowpipes, casting rings, and hand-cranked or spring-loaded centrifugal casting machines.

Mizzy, Dan D. and Durst, David L. (1940) Inlay Heater and Ring.US Patent 2,188,915. Fiiled May 26, 1937 and issued February 6, 1940.