Cured Rubber

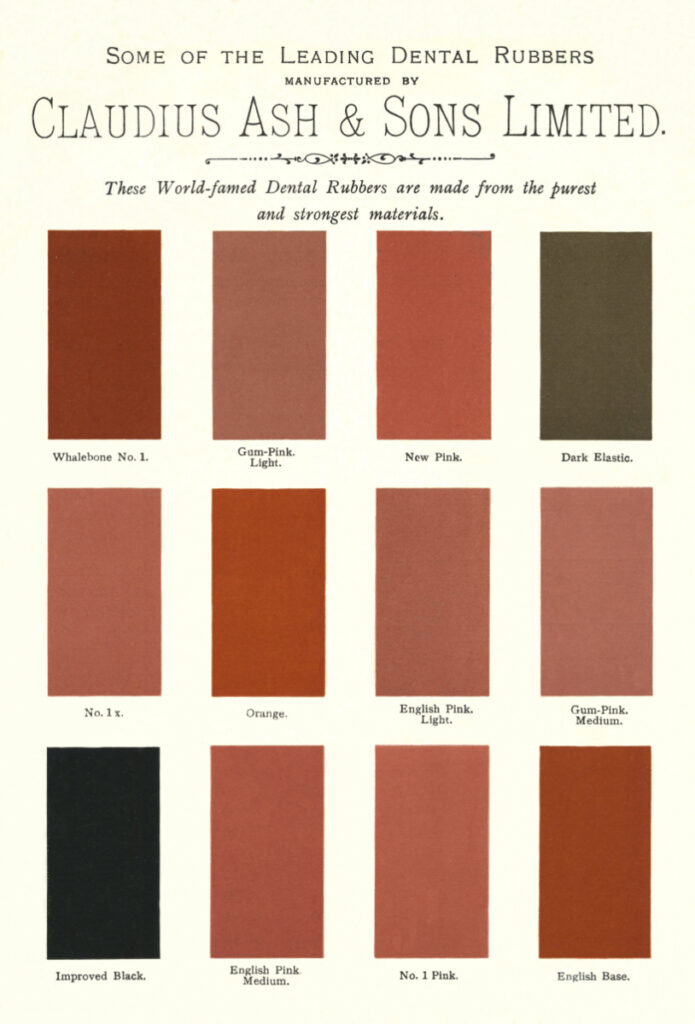

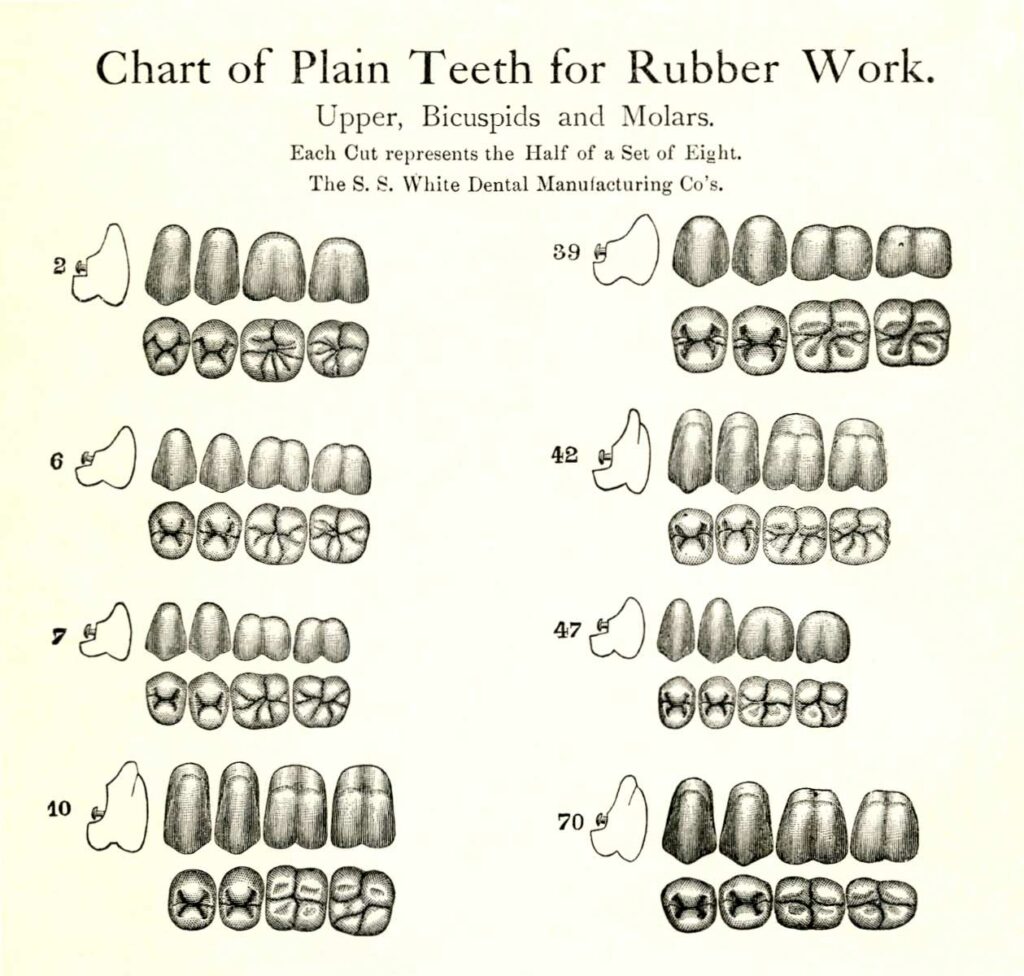

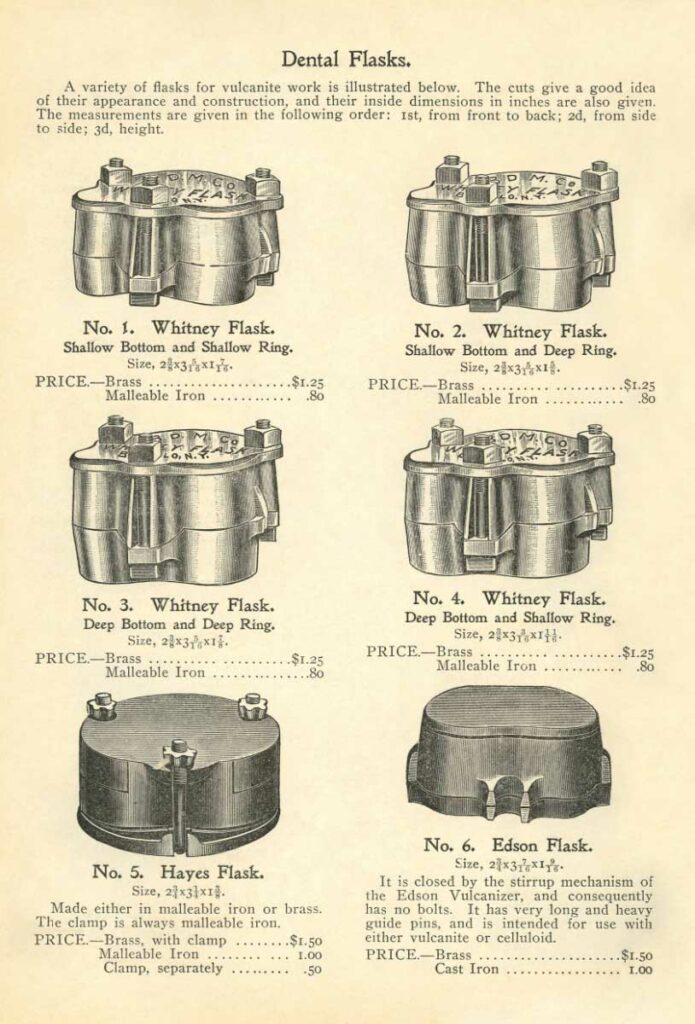

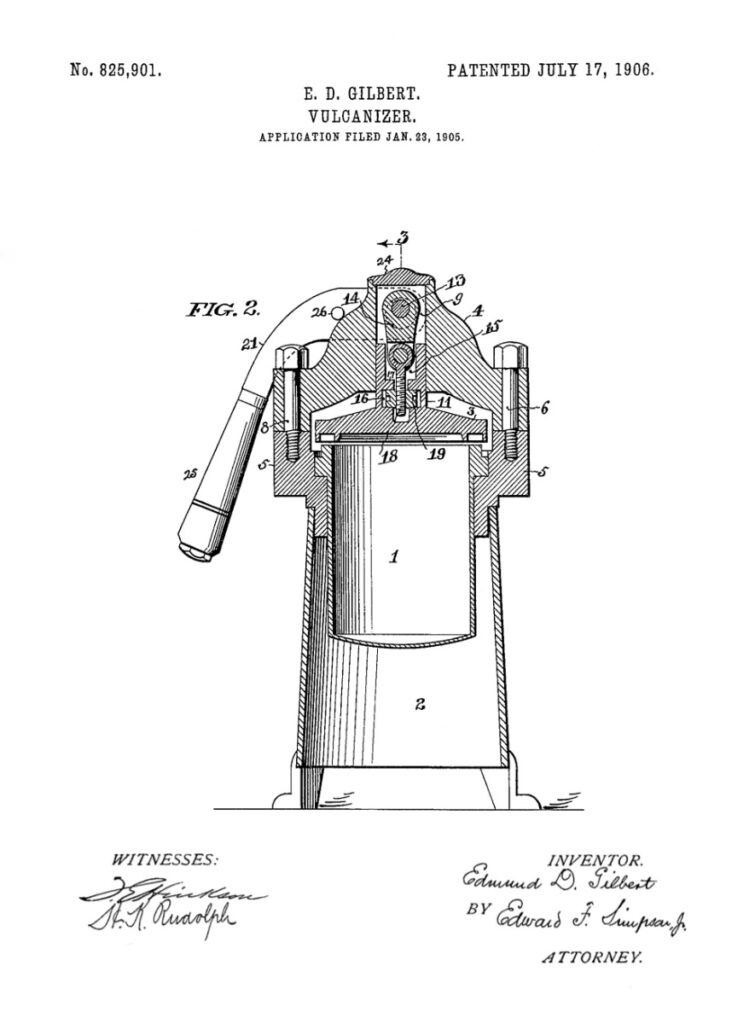

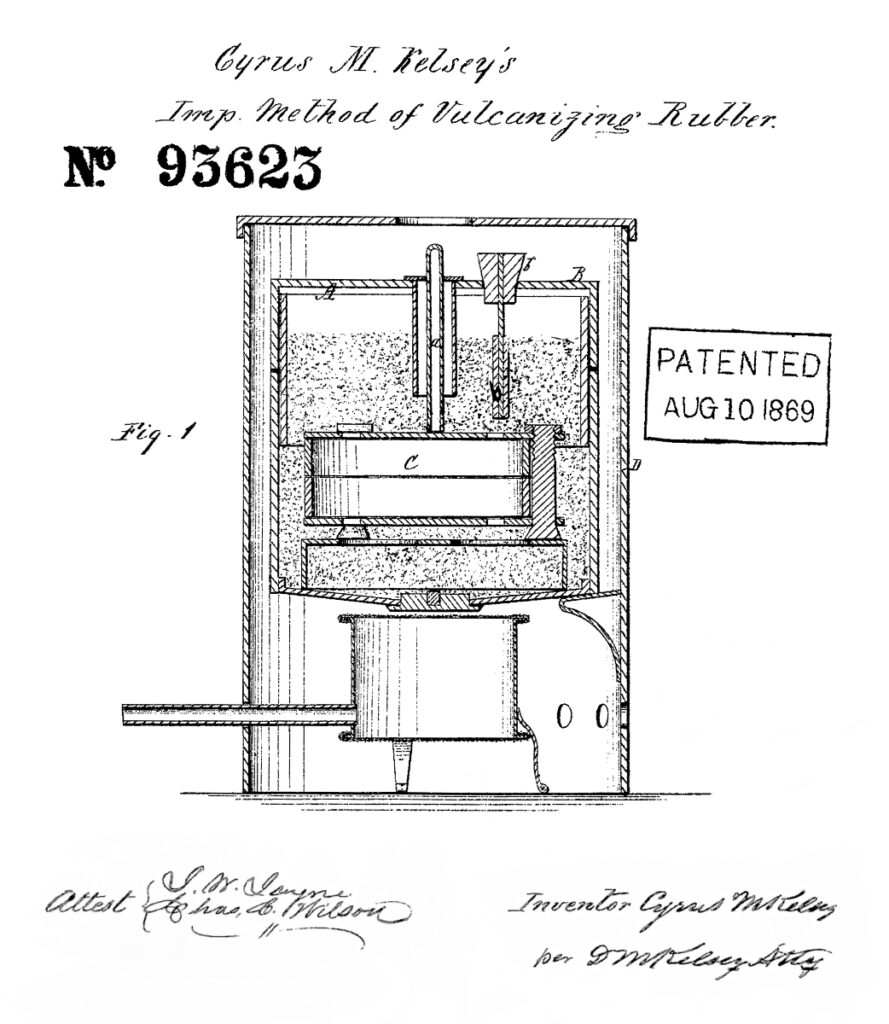

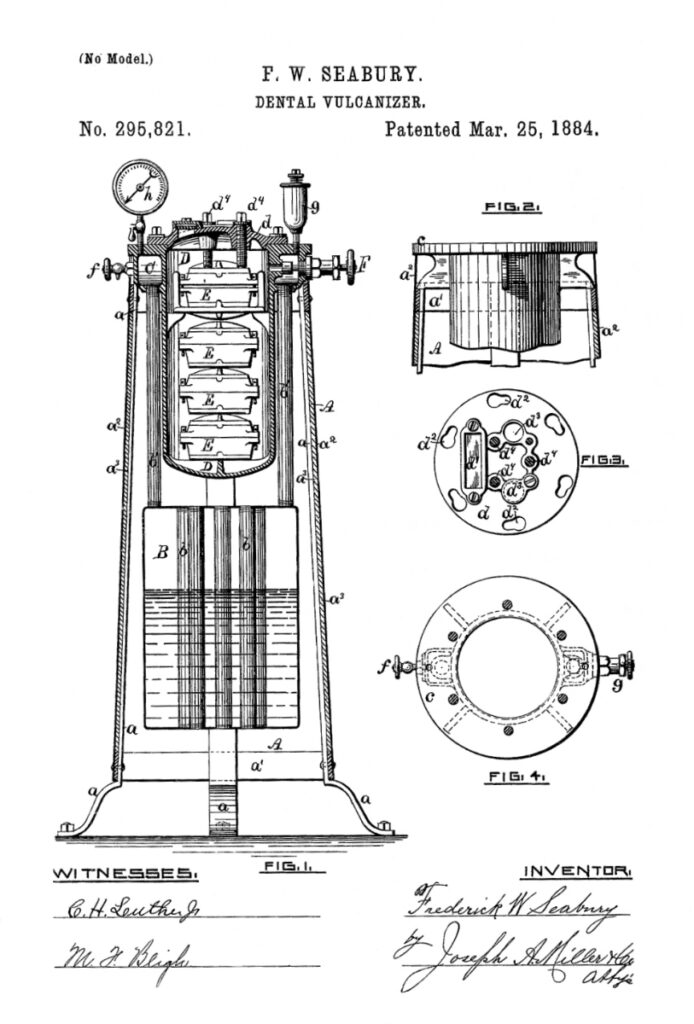

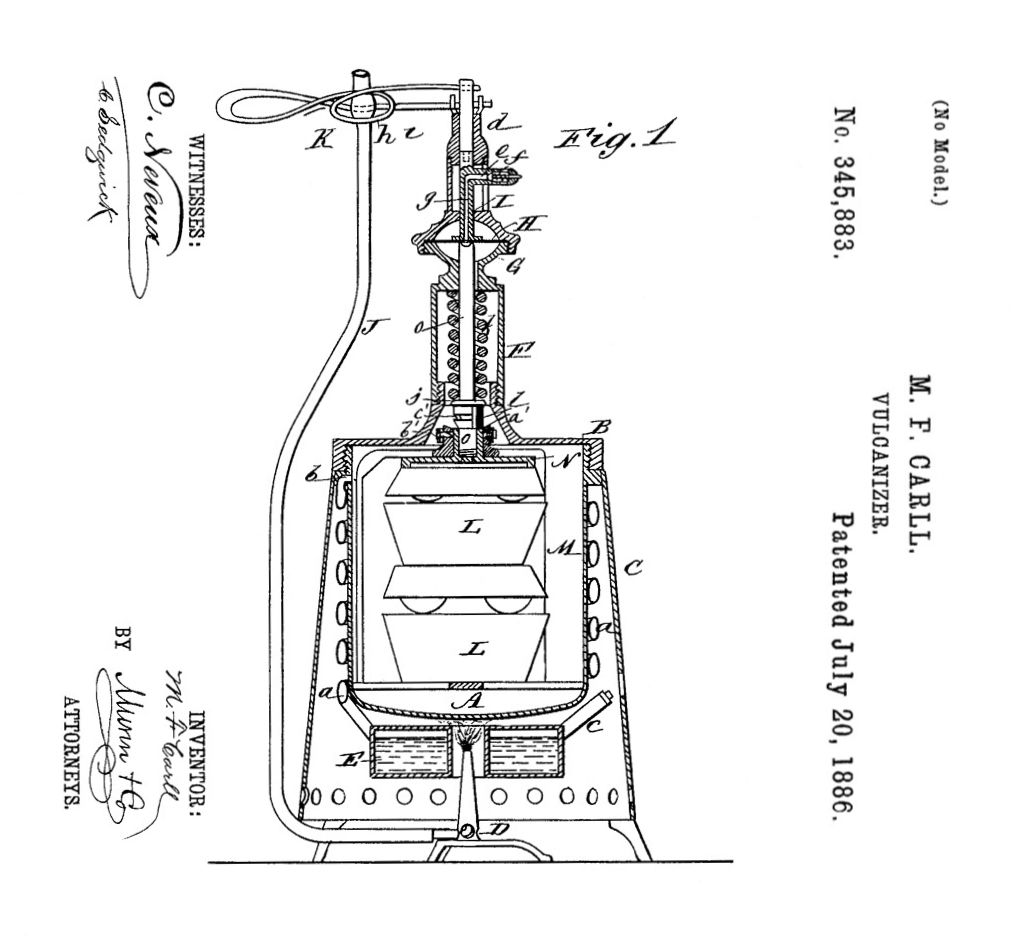

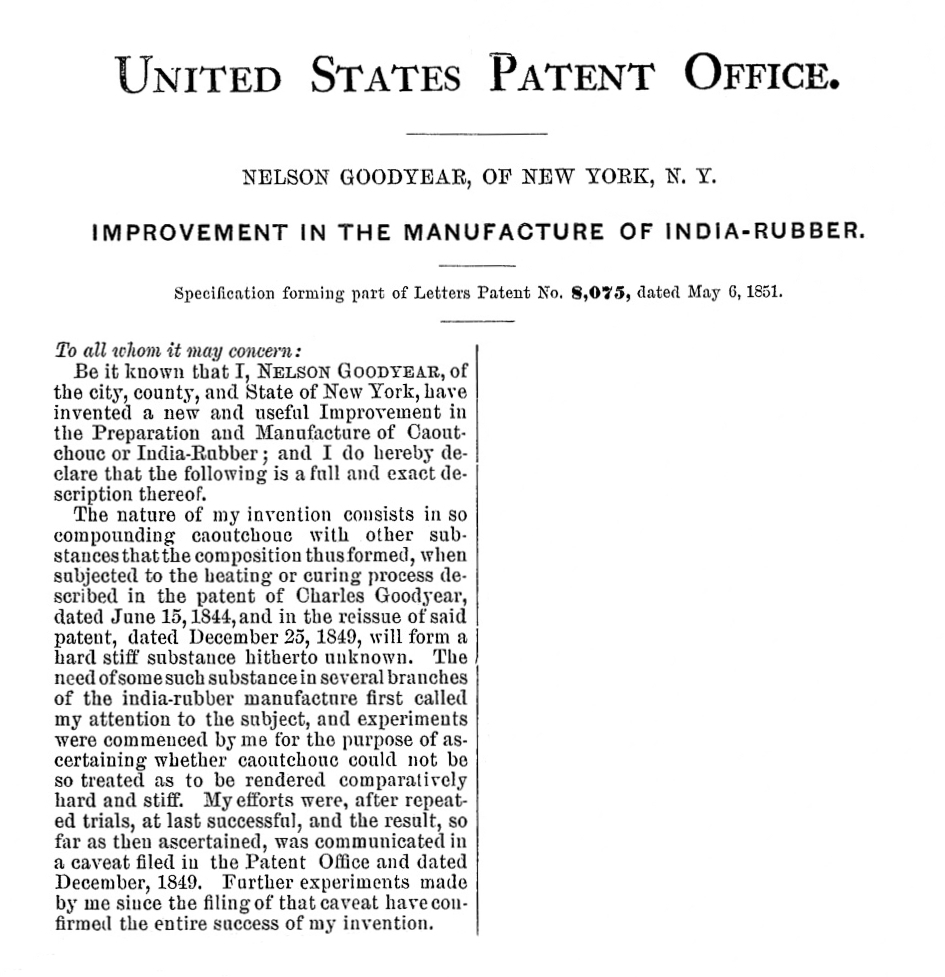

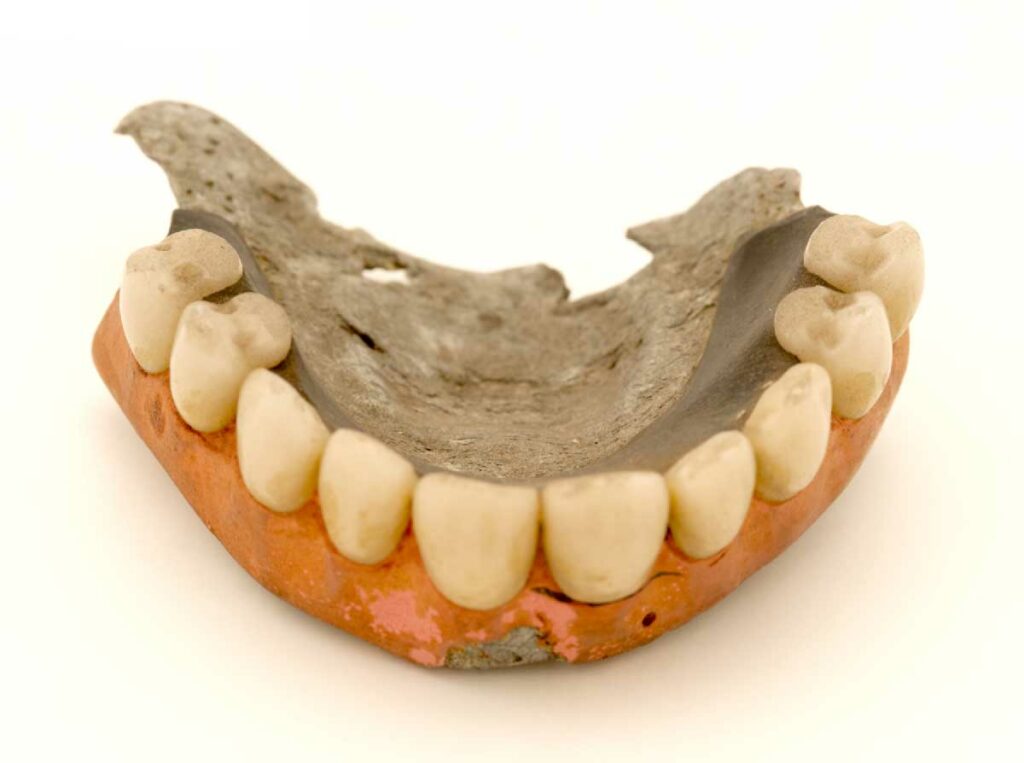

Beginning in the mid-1800s, natural rubber, combined with sulphur and coloring agents, was the material “cured” in a special oven to create what was called a vulcanite-based denture. Porcelain teeth, rather than being held in place by pins and soldered to a denture’s cast metal base, were inserted into the upper or lower denture while it was cradled within the lower half of a metal dental flask. Strips of prepared rubber material were packed into the mold, and the upper half of the dental flask screwed down tight. The flask and its contents were steam-heated under pressure in a vulcanizer oven. Initially, the rubber became soft enough to fill the mold crevices and surround the porcelain teeth. With additional heating, the rubber continued to cure, becoming vulcanized. Ideally, the process made a denture with teeth securely fixed in a fully hardened but flexible plate and gums.

Rueggeberg cites the authors of an 1891 dentistry textbook as they described the potential perils for the dentist using a vulcanite oven — “The pressure nearly doubles with the addition of each 50° of heat, and allowing a vulcanizer to run up to 400° or 420° is shown to be a piece of unpardonable carelessness and proceeding fraught with the greatest danger to life and property.” And, although it provided a satisfactory alternative to its predecessor — the laboriously constructed gold swaged denture of the early 1800s — vulcanite as a denture material had its disadvantages for the patient. Being porous, when improperly cured it succumbed to the moist environment of the mouth, becoming discolored and foul-smelling over time. Despite the dangers of its curing and the shortcomings of its use, vulcanite remained the denture material of choice from the mid-1800s to the 1930s.

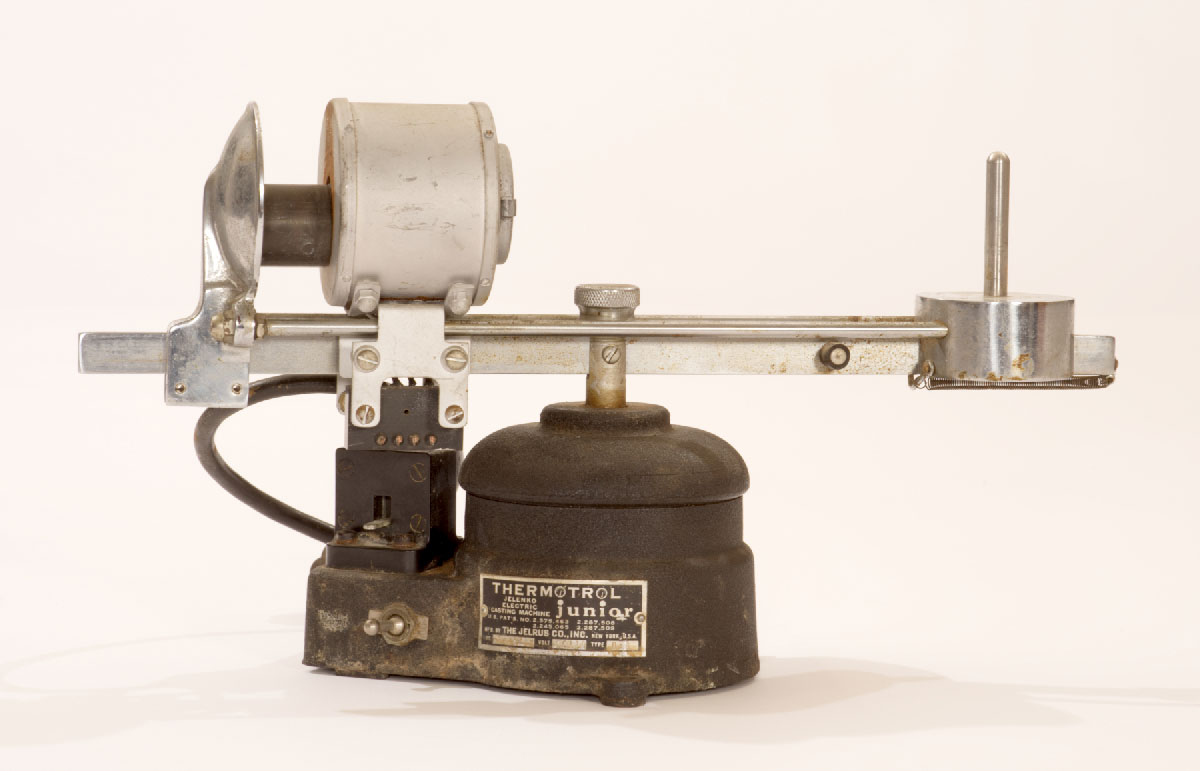

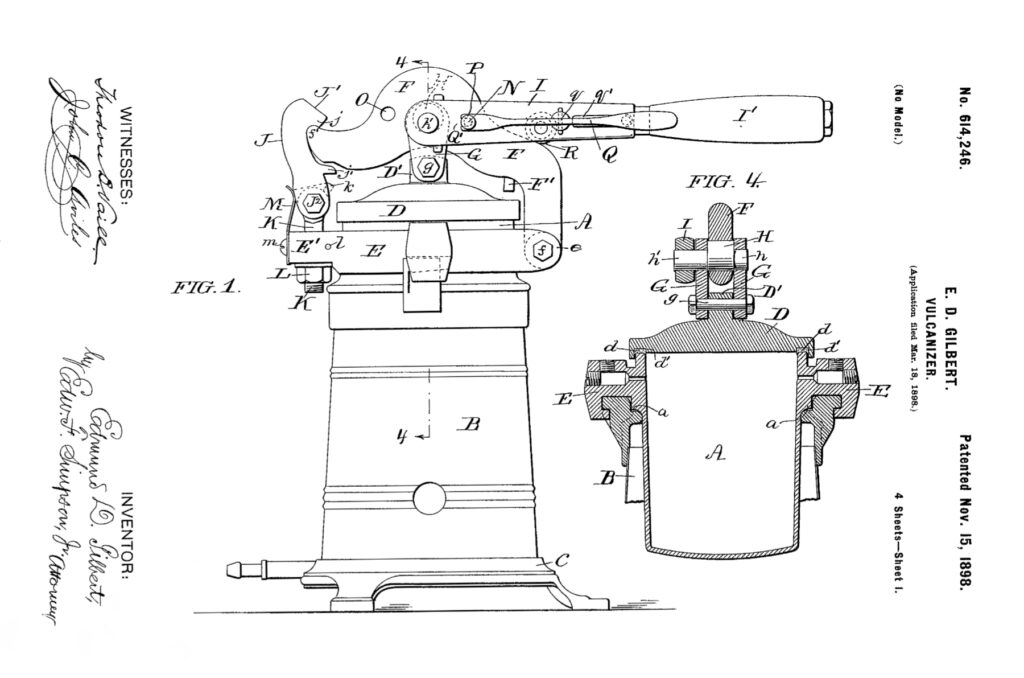

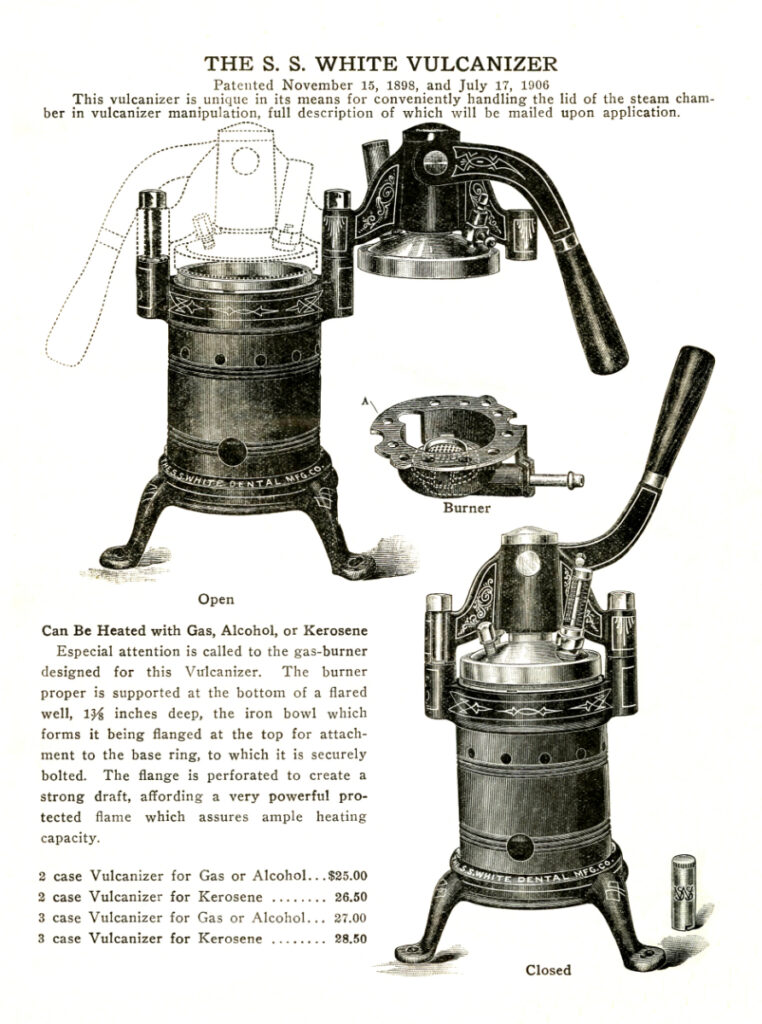

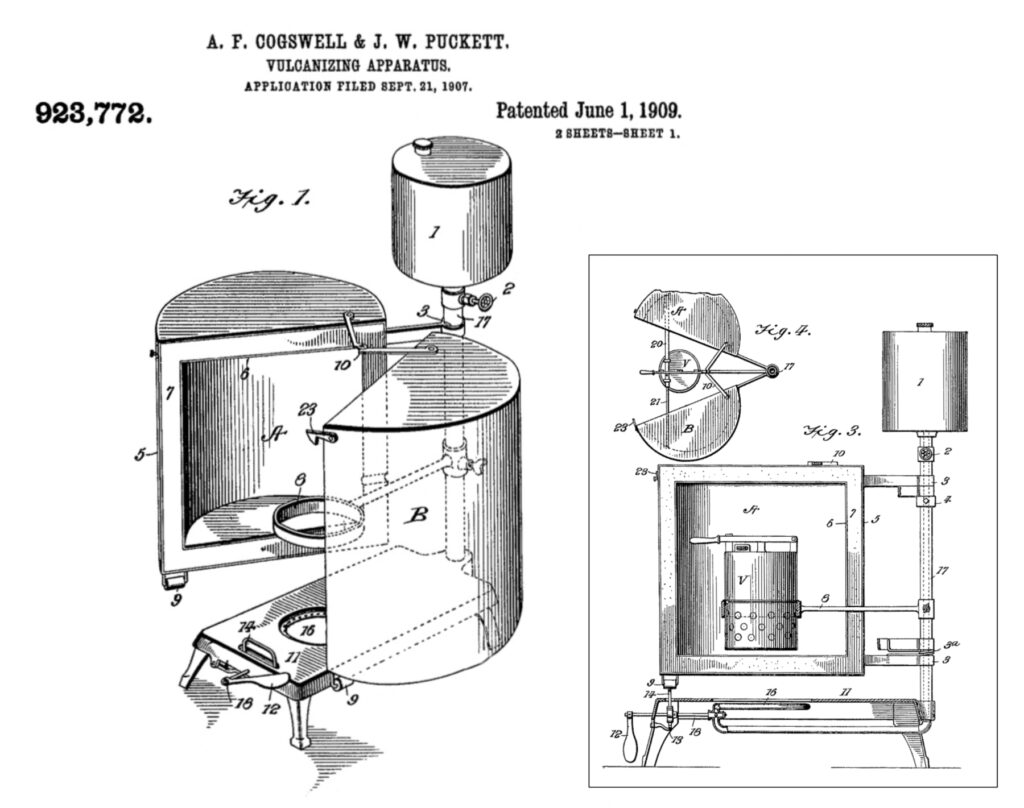

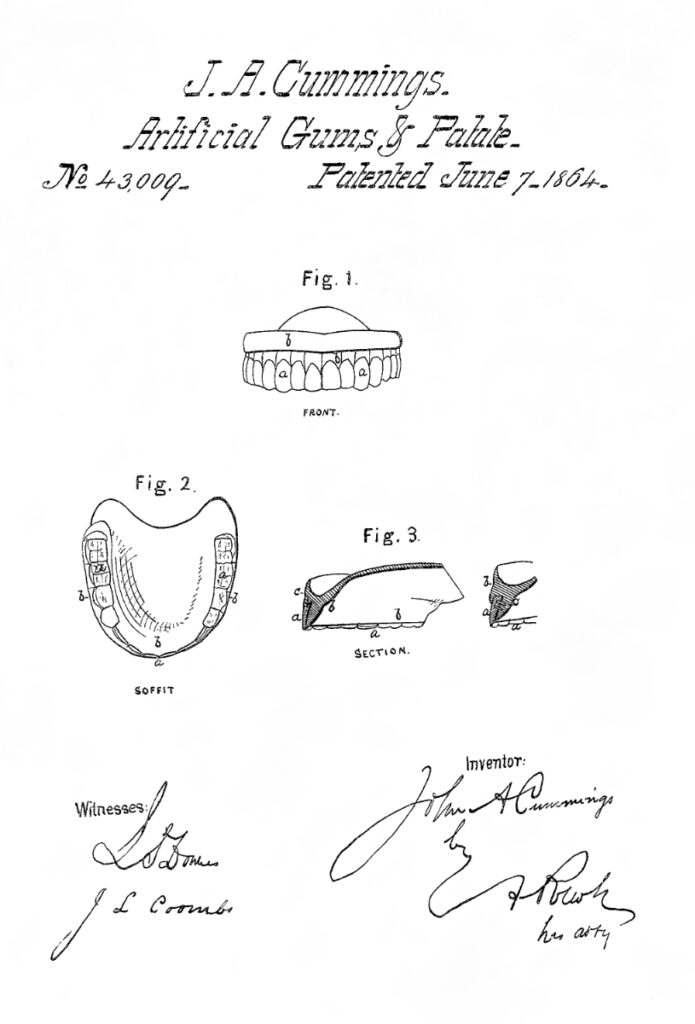

Shown here are several vulcanite ovens and related materials used by dentists making vulcanite dentures, including base rubber, artificial porcelain teeth, vulcanite dental flasks, and finished vulcanite dentures, as well as patents for vulcanite ovens (some showing their Bunsen burner heat sources), vulcanized rubber, and vulcanized dentures.

Glenner, R.A. 1997. How it evolved: The 19th Century Dentist’s Laboratory. J Hist Dent 45(1):23-25, March; Ring, M. E. 1984. The rubber denture murder case: The true story of the vulcanite litigations. Bull Hist Dent 32(1):3-18, April; Rueggeberg, F.A. 2002. From vulcanite to vinyl, a history of resins in restorative dentistry. J Pros Dent 87(4):364-379; Ladha, K. and Verma, M. 2011. 19th century denture base materials revisited. J Hist Dent 59(1):1-11; Williams, B. 2021. Denture-curing oven. Brit Dent J 231(1):11; Guyton, William R.A. (1938) Denture. US Patent 2,107,181. Filed April 4, 1935, and issued February 1, 1938; Gilbert, Edmund D. (1906) Vulcanizer. US Patent 825,901. Filed January 23, 1905, and issued July 17, 1906; Kelsey, Cyrus M. (1869) Improvement in Vulcanizing Rubber for Dental Plates and For Other Purposes. US Patent 93,623. Issued August 10, 1869.