Lost Wax

The “lost-wax” casting technique is a method of creating a mold by using heat in an oven (”burn-out oven”) to vaporize wax. In dentistry, the purpose was to make gold inlays or crowns, and the process started with a carefully prepared wax model (or pattern), the contours of which were meant to imitate natural tooth structure.

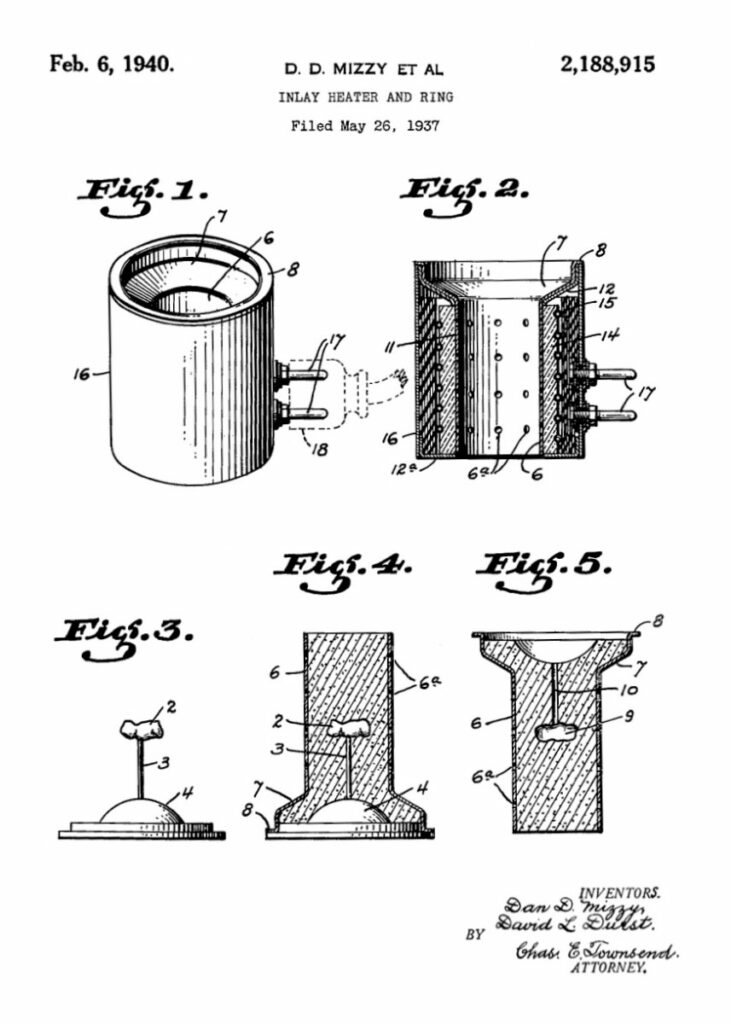

After preparation, in the case of an inlay or crown, the wax pattern was attached to a wax tube (“sprue”), with the sprue being attached to a conical-shaped metal base inside a metal casting ring. The ring was then carefully and completely filled with heat-resistant plaster of Paris, called the investment. After the investment fully hardened the conical metal base was removed, and the ring placed in the oven. The oven’s heat vaporized (“burned-out”) the wax pattern and wax sprue through the sprue hole, leaving the pattern’s mold. The heated casting ring containing the mold was then ready to receive the molten gold to be “thrown” by centrifugal force into the bottom of the conical investment base, down the sprue hole and into the wax pattern space (E. Giachetti, personal communication, April 29, 2022).

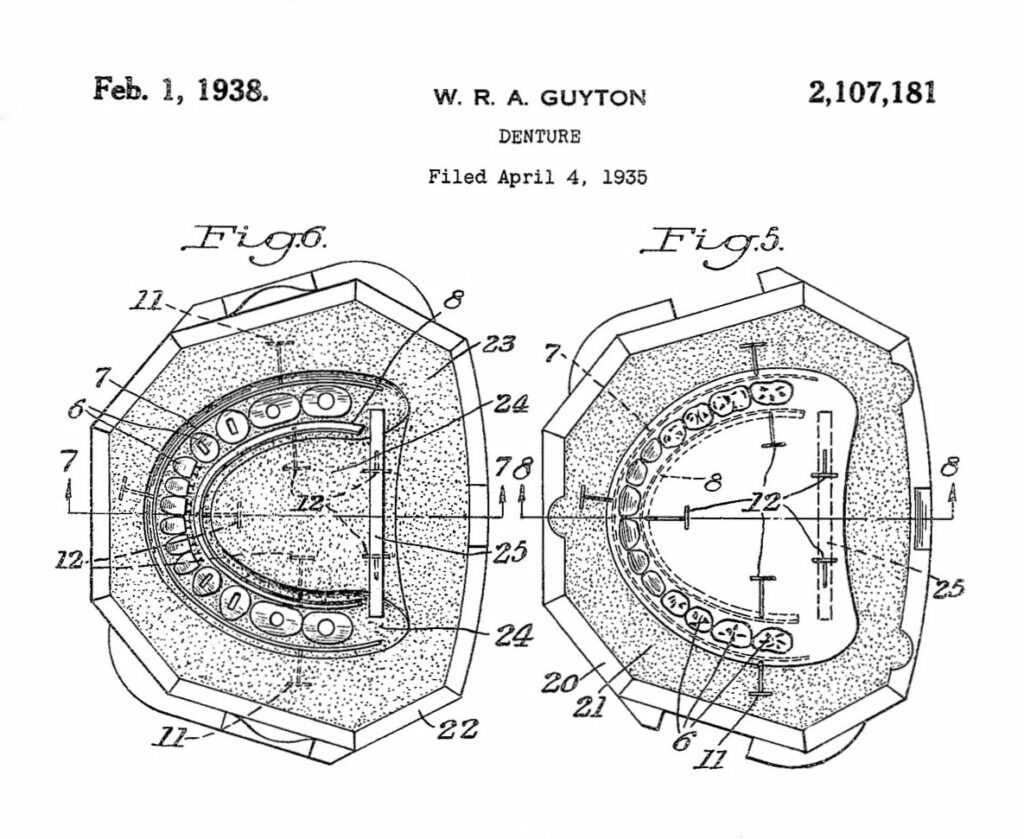

In the case of dentures, the completed “wax-up” was placed in a metal dental flask, the liquid plaster of Paris poured to envelope and harden around the teeth and wax, and the wax “burned-out” in the oven, leaving a hard shell mold.

A mold resulting from the lost-wax casting technique was used to make casts of the specific pattern in the appropriate material — porcelain, gold, vulcanite, celluloid, etc.

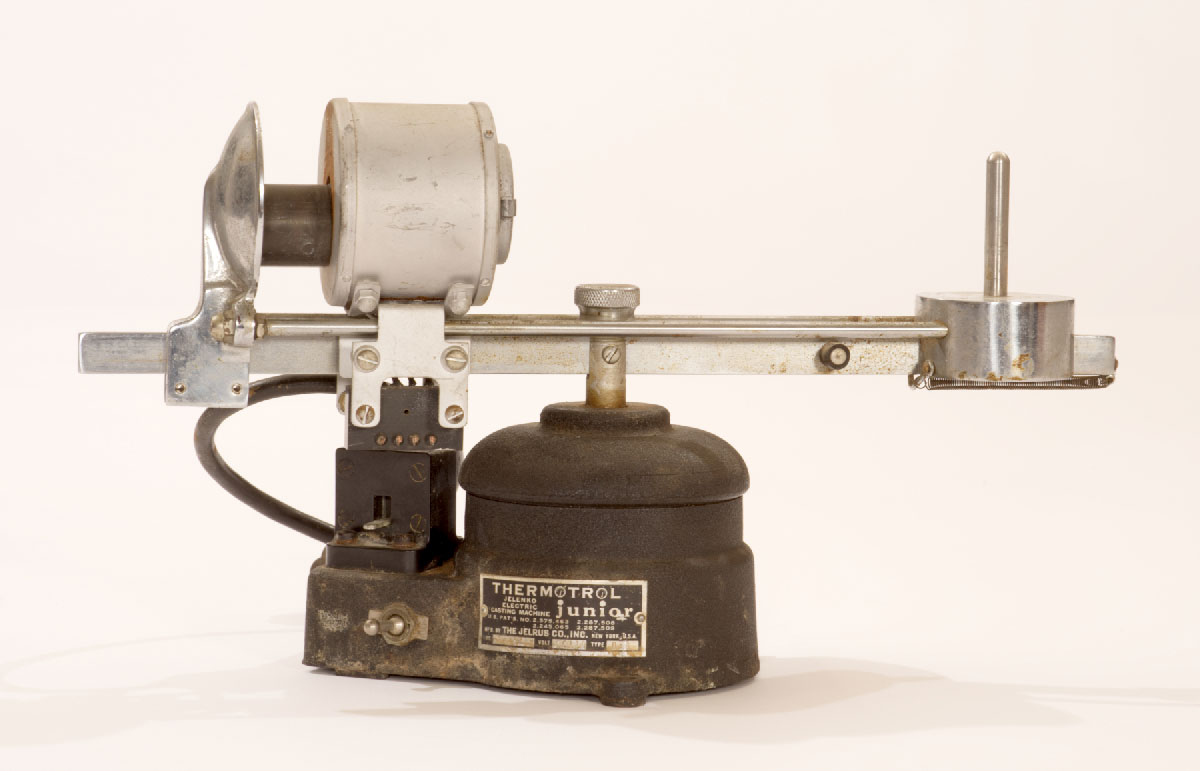

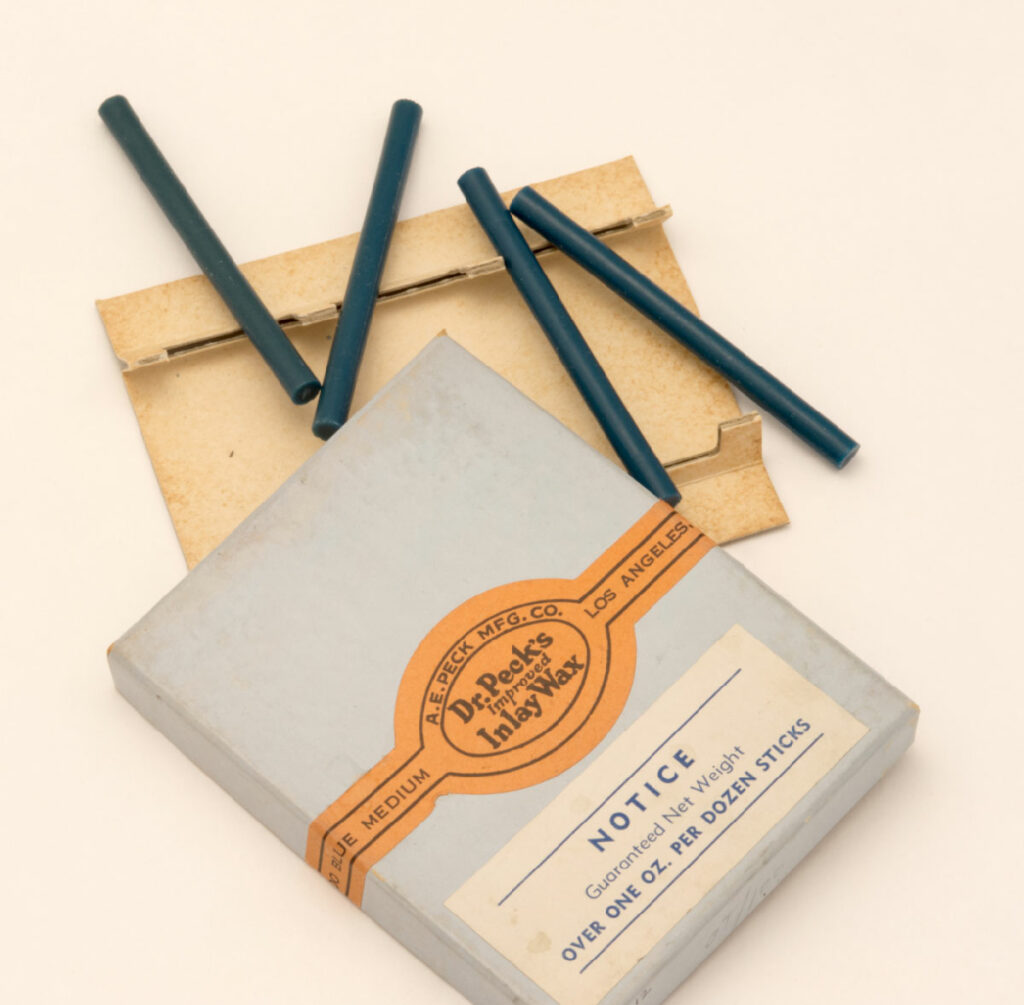

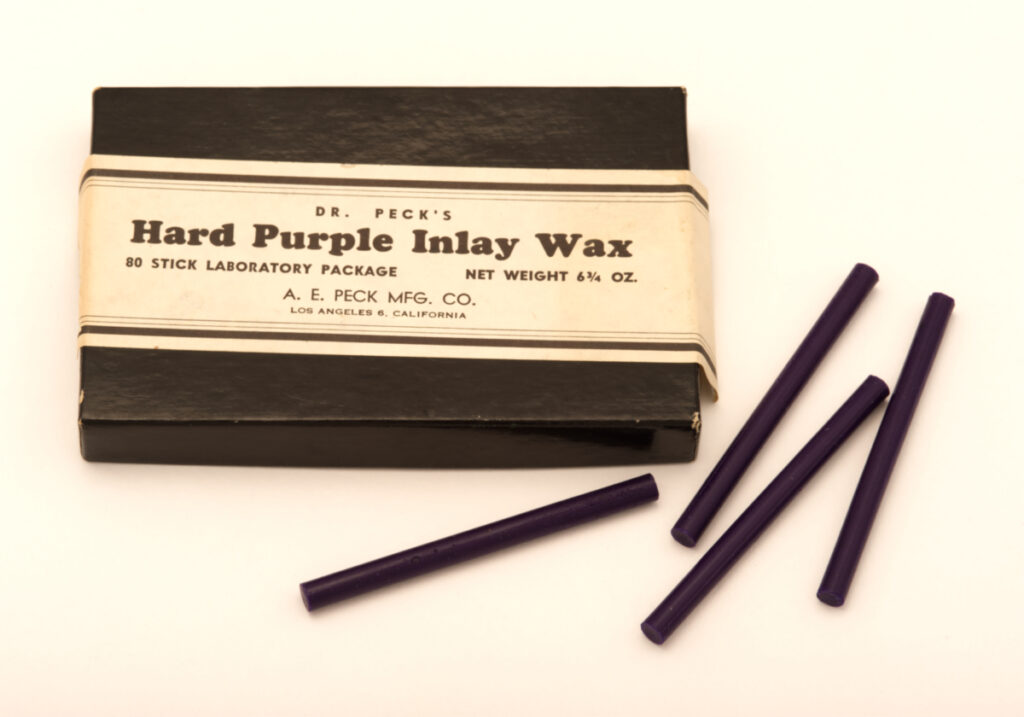

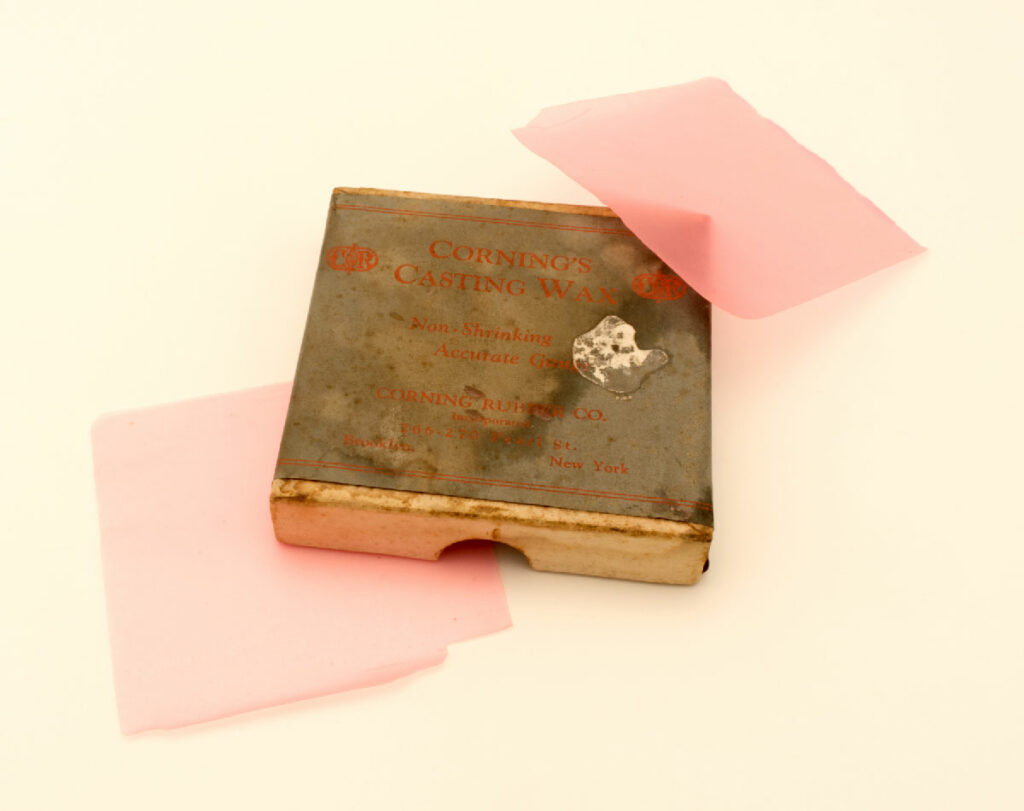

Shown here are several heating devices, and related materials, used by dentists practicing the lost-wax casting technique, including inlay wax and burn-out ovens, along with patents for a casting ring and a dental flask.

Mizzy, Dan D. and Durst, David L. (1940) Inlay Heater and Ring. US Patent 2,188,915. Filed May 26, 1937 and issued February 6, 1940; Guyton, William R.A .(1938) Denture, US Patent 2,107,181. Filed April 4, 1935, and issued February 1, 1938.